Article successfully added.

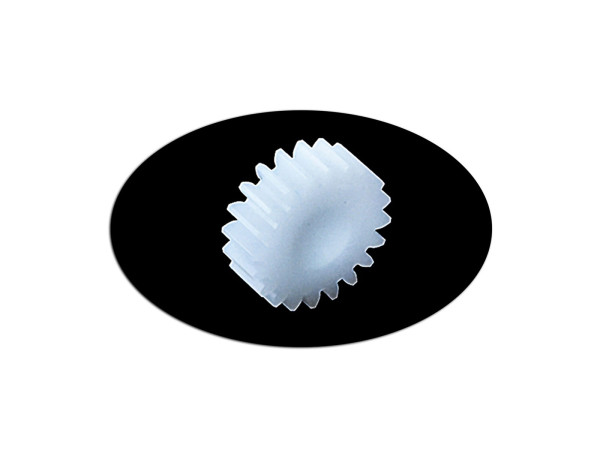

26.33€*

29.33€*

Prices incl. VAT plus shipping costs

Available immediately

This item will be shipped today if you order within 14 hours and 28 minutes!

- Order number: 2537

- Manufacturer: partworks